Meticulous selection for top grade quality.

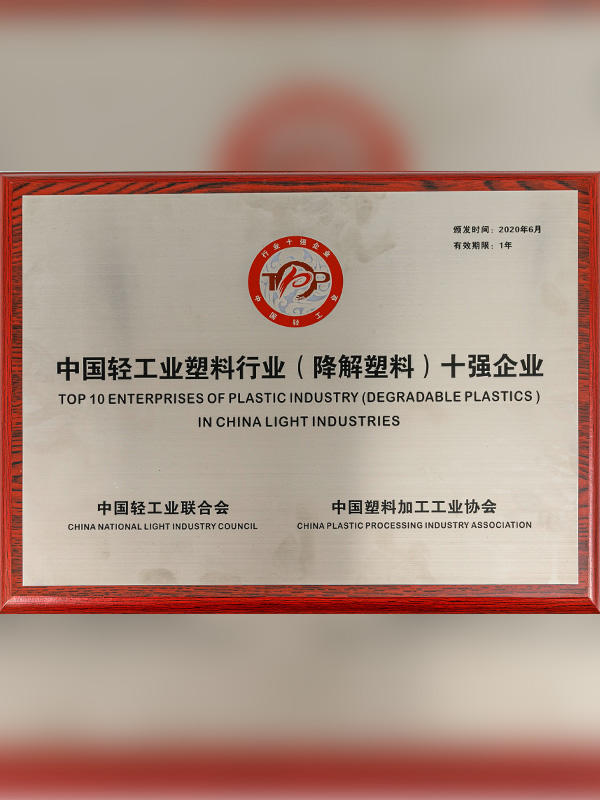

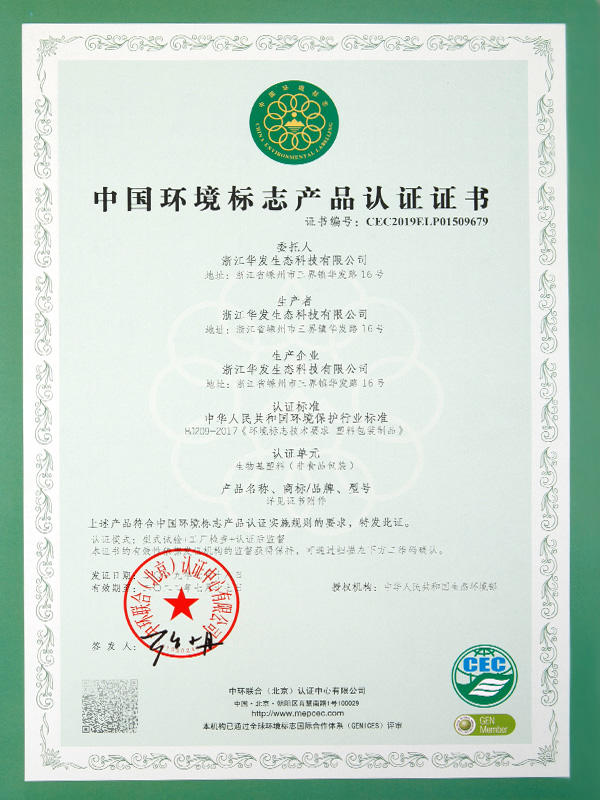

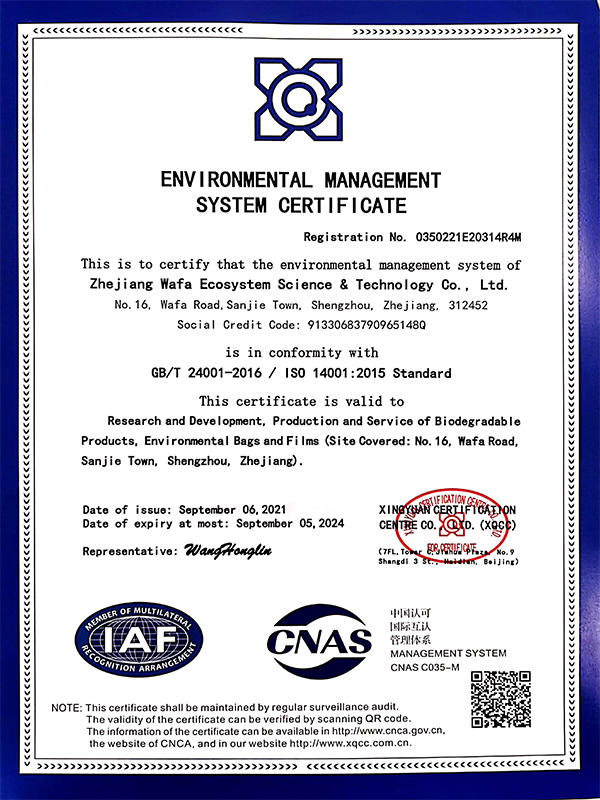

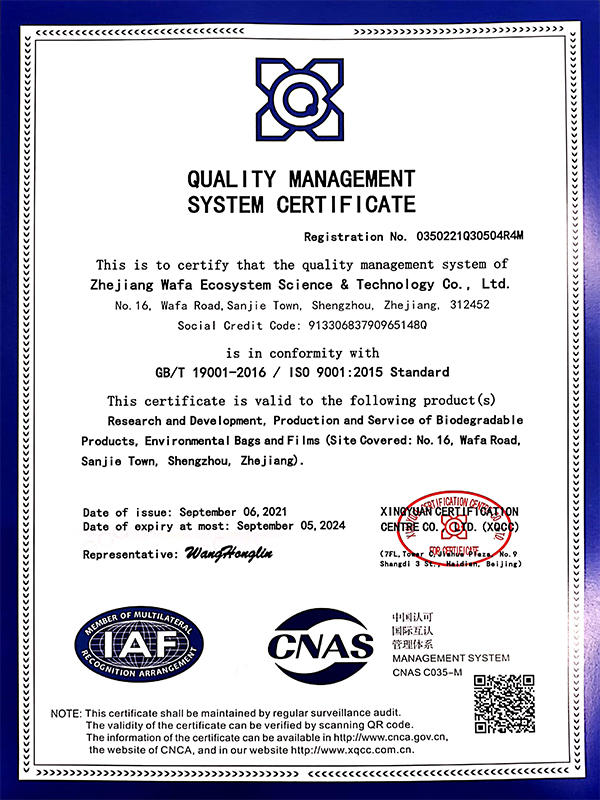

Zhejiang Wafa Ecosystem Science and Technology Co., Ltd. is a national high-tech enterprise specializing in the production and sale of bio-based materials and biodegradable products. Through the establishment of a complete industrial chain such as technology research and development, material production, product design, manufacturing and terminal market development, our company has provided many outstanding companies around the world, including the world's top 500 companies, with comprehensive green packaging solutions to jointly achieve the goal of environmental protection, energy saving, and reduction of carbon emissions. We are China Green Polyethylene Material Factory and Wholesale Green PE Material Company. The products are widely used in: Bio-based, biodegradable products manufacturing enterprises, large supermarkets and catering industry, etc. The company have established cooperative relations with Walmart and McDonald's. The products are also exported to more than 20 countries and regions around the world, such as Canada, Japan, the United States, Mexico, etc. Wafa is the vice chairman units of of Degradable Plastic Committee in China Plastics Processing Industry Association (CPPIA) and member unit of China Biodegradation Standards Committee (TC380). The company has passed ISO9001, ISO 14001 and ISO 45001, its products have been certified by EN13432, ASTM d6400, ASTM D6866, OK COMPOST, OK-BIOBASED, FDA and China Environmental labeling products certification. At the same time, the company has also passed the ES, SCS, SWA, GMP, FCCA, BSCI and other audits from Walmart and McDonald, as well as supplier audits of SF-express, Meituan takeout and ELEME takeout, and obtained BRC audit certification of EU. The company has more than 200 intellectual property rights. Wafa is committed to become a global outstanding manufacturer of bio-based materials. We sincerely welcome all friends to our company for guidance and investigation.

English

English 中文简体

中文简体 日本語

日本語

ta8012005205_en_ed20201215.jpg?imageView2/2/format/jp2)