There are several biodegradable materials that can be used for film blowing. Some of the most common options include:

1.PLA (Polylactic Acid): This is a bioplastic made from renewable resources such as corn starch or sugarcane. It is compostable and biodegradable under industrial composting conditions.

2.PHA (Polyhydroxyalkanoates): PHA is a biopolymer produced by bacteria that can degrade in a variety of environments, including soil, water, and marine environments.

3.Starch-based bioplastics: These are made from various types of starch, such as corn, potato, and tapioca, and are fully biodegradable and compostable.

4.Cellulose-based bioplastics: These are made from cellulose, which is a renewable resource derived from plant material. They are fully biodegradable and compostable.

There are several advantages of using

biodegradable materials for film blowing, including:

1.Environmental sustainability: Biodegradable materials are made from natural sources such as plant starch, cellulose, and other renewable resources. Unlike traditional plastic films, biodegradable films can decompose into harmless natural substances without polluting the environment.

2.Reduced landfill waste: Biodegradable films can break down naturally over time, reducing the amount of waste that ends up in landfills. This can help to alleviate the strain on landfill capacity and reduce the amount of greenhouse gases produced by the decomposition of organic waste in landfills.

3.Cost-effective: Biodegradable films can be cost-competitive with traditional plastic films, and in some cases, may even be less expensive. As the demand for biodegradable films increases, the cost of producing them is likely to decrease further.

4.Versatility: Biodegradable films can be used in a wide range of applications, including food packaging, agriculture, and construction. They can be tailored to meet specific performance requirements, such as strength, flexibility, and barrier properties.

5.Health and safety: Biodegradable films are often free from harmful chemicals and additives, making them a safer and healthier option for both humans and the environment. They can also be composted, reducing the need for pesticides and other chemicals in agriculture.

When choosing a biodegradable material for film blowing, there are several factors that you should consider to ensure that the material is suitable for your specific application. Here are some important things to keep in mind:

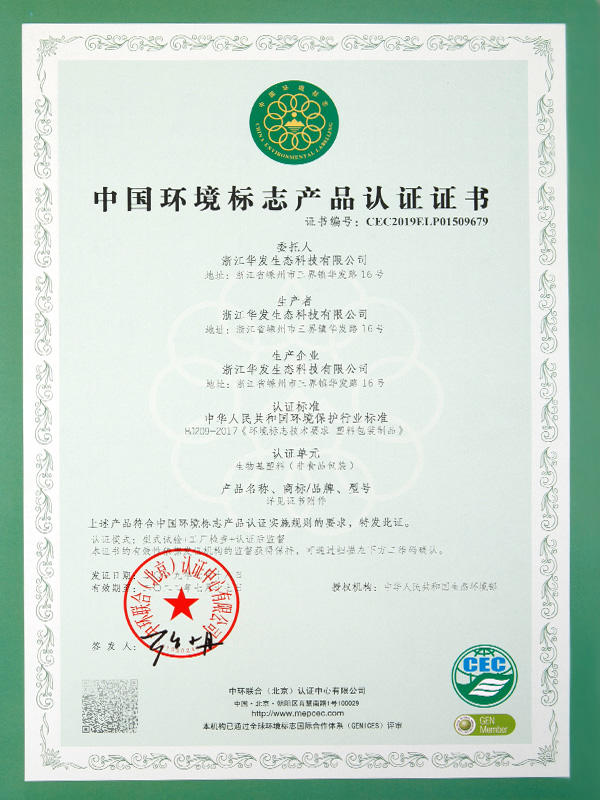

1.Biodegradability: Look for materials that are certified as biodegradable by reputable organizations such as the Biodegradable Products Institute (BPI) or the European Bioplastics Association (EUBP). Make sure that the material will break down into natural elements under specific conditions, such as exposure to sunlight, moisture, and microorganisms.

2.Performance: Consider the performance characteristics of the material, such as strength, durability, flexibility, and temperature resistance. Choose a material that will meet your specific requirements for your application, such as load capacity or storage conditions.

3.Compatibility: Make sure that the biodegradable material is compatible with your production equipment and processes. Some materials may require specific processing conditions, such as temperature or speed, that may affect the quality of the film.

4.Cost: Consider the cost of the material compared to traditional non-biodegradable materials. While biodegradable materials may be more expensive, they may also provide benefits such as improved environmental sustainability and consumer appeal.

5.Regulatory Compliance: Ensure that the chosen biodegradable material meets all relevant regulatory requirements, such as food contact approvals and compliance with environmental regulations.

6.End-of-life: Consider the end-of-life options for the biodegradable film. Some materials may require specific disposal methods, such as composting, while others may be recyclable or able to biodegrade in landfill conditions.

By taking these factors into consideration, you can choose a biodegradable material that will provide the performance and environmental benefits you need for your film blowing application.

English

English 中文简体

中文简体 日本語

日本語

ta8012005205_en_ed20201215.jpg?imageView2/2/format/jp2)